Good Suggestions For Deciding On Packaging Equipment

Wiki Article

What Are The Main Differences Between The Packaging Equipment For Food, Industrial And Cosmetic Products?

Different industries need different packaging machines. Each industry has its own requirements. They are built to last and come with the latest technology that guarantees accurate and efficient packaging.

Food packaging machines Food packaging equipment is specifically designed to meet strict hygiene and safety requirements. They typically have simple to use surfaces, advanced sanitation systems, temperature control features, and other features to ensure the safety and the quality of packaged food items.

Cosmetic packaging equipment Cosmetic packaging equipment is specifically designed to handle delicate containers like small vials. They are fitted with gentle handling systems that ensure the products are packed with care.

Pharmaceutical packaging equipment They were developed to meet the strictest safety and regulatory standards. A lot of machines feature sophisticated labeling capabilities, dosing systems that are exact and tamper-proof and sophisticated labels to ensure safety and quality of pharmaceutical products packaged.

Packaging machines for household items They are designed to package a variety of household items like detergents, cleaning supplies and personal care items. They typically have features like multiple-head packaging and flexible configurations for packaging. filling system to ensure that household products are packaged efficiently and efficiently.

In conclusion, packaging machines for various industries differ according to the specific needs of each sector, which include dimensions and shapes of products packaging material, size and shape, as well as desired output, and are specifically designed to meet the unique specifications and requirements of every sector. Take a look at the most popular Automatisation pour développer votre activité for blog recommendations..

What Are Some Quick And Effective Packaging Solutions For Industrial Companies

Small packaging for the industrial Sector- Automation could be utilized to manage small packaging in the industrial industry. Multi-head weighers and small-format packaging equipment, like vertical fill sealing machines as well as small format packaging equipment, can help increase efficiency. Automated storage management systems can also be used to optimize the storage and retrieval of small packaging.Palletizing for Long Periods- Robotic palletizing systems can be used to improve the efficiency of the palletizing process, while also reducing the risk of injury to operators. They can handle a wide range of packages and are able to be programmed so that they can process pallets at speeds of high speed.

Care of fragile vials and small vials Packaging equipment that is specially designed can be used, such as blister packing machines, to take care of fragile vials within the beauty-cosmetics business. These machines will guarantee that vials and containers can be securely packed and shipped with little handling, thereby reducing the chance of damage.

Packaging equipment and manufacturing processes should be selected in accordance with the specific needs of the product. A preventative maintenance program should be put in place to ensure the machine will continue to function efficiently and effectively throughout the time. View the recommended Industries industriel, alimentaire, cosmétique, pharmaceutique, produits ménagers for website info..

Define A Variety Of Equipment And Systems Used In The Food And Beverage Sector

Blast Chillers- Blast chillers could be specially designed refrigeration units that lower the temperature quickly of food items that are hot to prevent the growth of harmful bacteria. They are commonly employed in the food industry to improve the safety of food and to preserve perishable foods. These solutions increase efficiency while maintaining high quality.

Packaging of Trays & Cardboard Boxes Packaging equipment such as case erectors, tray makers, and case erectors may be used to pack food products in cardboard boxes or tray. These machines can create the tray or the box and pack it with food items. Then seal the package with a single automated method.

Shrink Sleeves- Shrink sleeves are able to easily be placed on beverages or food containers using shrink sleeves machines. The shrink sleeves are placed on top of the containers and then heated to cause them to shrink and conform to their shapes. This produces attractive packaging for food products and beverages that is secure and tamperproof.

In all instances it is crucial to take into consideration the particular needs of the food and beverage item, like size as well as shape and fragility, when selecting the appropriate packaging equipment. The equipment should also be in compliance with the requirements for food safety, like the ones set by FDA and USDA to ensure that packaged food items are safe to consume. See the top Bière emballée à une vitesse de 20 à 30 caisses par minute for site tips..

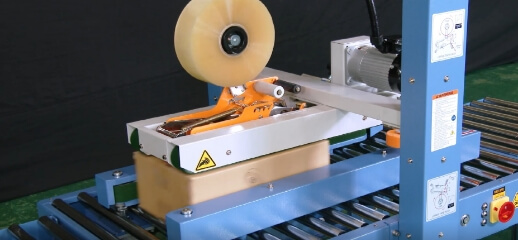

Wrap-Around Case Packer For Automatic Feeds And Magazines That Are Flatbed

Wrap-around Case Packers are a type or machine that packs boxes in a wrap-around fashion. It is typically a feed system which can be used to accommodate different quantities of boxes. The machine is fitted with a feed system that allows boxes to be fed at an even frequency. This flexibility is a perfect fit for a range of industries and applications.

The casepacker that wraps around comes with an adjustable flatbed magazine. This magazine is adjusted to fit different shapes and sizes of boxes. The machine is able to be used for a wide range of packaging applications without having to make any adjustments or alter the tools.

Alongside its flexibility and user-friendliness Wrap-around case packs are specifically designed to be efficient, and they are typically equipped with modern capabilities like robotics and programmable logic controllers. These features are specifically designed to allow the machine to run efficiently in production environments with high volumes.

A wrap-around casepacker equipped with an adjustable flatbed magazine and automated feeds is a cost-effective and affordable option for many packaging requirements. It also helps increase productivity and speed up operations in various industrial settings. Read the most popular industries et sécurité sur le lieu de travail for website tips..

Automated Packaging Systems Can Be Customized To Suit Food, Industrial, Cosmetics, And Pharmaceutical Products

Tailor-made automated packaging systems are custom packaging solutions that are customized to specific industries, including cosmetics, food and pharmaceutical. These systems are able to optimize manufacturing processes, boost efficiency, and address the specific needs of the industry.

Flexible packaging configurations for customizing The packaging configurations for these systems can be customized to meet the particular requirements of every industry, which includes the size and shape of the product, as well as the type of packaging material, as well as the output desired.

Production processes that are efficient- Tailor-made automated packaging systems boost production efficiency and minimize downtime. They are suitable for environments that require high volumes of production.

Modern technology- These systems are equipped with state-of-the-art technology, including programmable logic controllers, robotics, and advanced sensors, to ensure reliable and precise operation.

Quality control- These custom-designed automated packaging systems can help reduce waste, boost satisfaction of customers and guarantee product safety.

Cost-effectiveness- These systems could be used to reduce packaging costs while still delivering excellent results.

In short, customized automatic packaging systems allow for specific industry requirements to be met. They aid in optimizing the process of packaging, improve productivity, decrease costs and increase overall profits. Read the top Emballage for website advice..